Top Cloud-Based CRM Platforms: Enhancing Business Efficiency With Innovative Solutions

Top Cloud-Based CRM Platforms sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. Cloud-based CRM platforms have revolutionized the way businesses manage customer relationships, providing unprecedented flexibility and scalability. In this exploration, we delve into the top contenders in this dynamic field, highlighting their key features and benefits for businesses of all sizes.

Overview of Top Cloud-Based CRM Platforms

Cloud-based CRM platforms offer businesses a flexible and scalable solution for managing customer relationships and interactions. These platforms are hosted on remote servers and accessed through the internet, providing easy deployment and accessibility from anywhere.

Top Features of Cloud-Based CRM Platforms

- Centralized Customer Data: Cloud-based CRM platforms store all customer information in one centralized location, allowing for easy access and updating.

- Scalability: These platforms can easily scale up or down based on business needs, making them suitable for businesses of all sizes.

- Automation: Cloud-based CRM platforms offer automation features for tasks like email marketing, lead management, and customer service, improving efficiency.

- Integration Capabilities: Integration with other business tools and applications allows for a seamless flow of data and information across different platforms.

- Mobile Access: Cloud-based CRM platforms are accessible on mobile devices, enabling sales teams to stay connected and productive on the go.

Benefits of Using Cloud-Based CRM Platforms for Businesses

- Cost-Effective: Cloud-based CRM platforms eliminate the need for expensive hardware and maintenance costs, making them a more affordable option for businesses.

- Flexibility: Businesses can easily customize and tailor cloud-based CRM platforms to suit their specific needs and requirements.

- Real-Time Updates: Cloud-based CRM platforms provide real-time updates and insights, allowing businesses to make informed decisions quickly.

- Improved Collaboration: Cloud-based CRM platforms enable teams to collaborate effectively, share information, and work together towards common goals.

- Enhanced Security: Cloud-based CRM platforms offer robust security features to protect sensitive customer data, ensuring compliance with data protection regulations.

Salesforce CRM

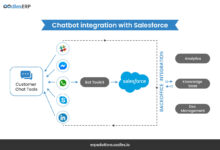

Salesforce CRM is a cloud-based customer relationship management platform that offers a wide range of features to help businesses manage their customer interactions effectively.

Key Features and Functionalities of Salesforce CRM

- Lead Management: Salesforce CRM allows businesses to track and manage leads efficiently, helping to convert them into customers.

- Sales Automation: The platform automates various sales processes, streamlining workflows and increasing productivity.

- Marketing Automation: Salesforce CRM enables targeted marketing campaigns and personalized communication with customers.

- Customer Service Management: Businesses can provide excellent customer service through Salesforce CRM’s ticketing system and knowledge base.

- Analytics and Reporting: The platform offers robust analytics and reporting tools to help businesses gain insights into their sales and marketing performance.

Comparison of Salesforce CRM with other Cloud-Based CRM Platforms in Terms of Scalability

Salesforce CRM stands out in terms of scalability compared to other cloud-based CRM platforms. It offers a highly scalable infrastructure that can grow with businesses of all sizes. The platform can easily accommodate a growing customer base and increasing data volume without compromising performance.

How Salesforce CRM Helps Businesses in Managing Customer Relationships Effectively

- Centralized Customer Data: Salesforce CRM provides a centralized database for storing all customer information, ensuring easy access and efficient management.

- Personalized Interactions: Businesses can personalize interactions with customers by leveraging Salesforce CRM’s data insights and automation capabilities.

- Improved Communication: The platform enables seamless communication with customers through various channels, enhancing customer engagement and satisfaction.

- Enhanced Collaboration: Salesforce CRM fosters collaboration among team members, allowing them to work together towards a common goal of satisfying customers.

HubSpot CRM

HubSpot CRM is a cloud-based solution that offers unique selling points catering to the needs of businesses looking to streamline their customer relationship management processes efficiently.

Unique Selling Points

- HubSpot CRM provides a user-friendly interface that is easy to navigate, making it simple for teams to adopt and use effectively.

- It offers robust marketing automation features, allowing businesses to create targeted campaigns and track customer interactions seamlessly.

- HubSpot CRM integrates seamlessly with other HubSpot tools such as the Marketing Hub and Sales Hub, providing a comprehensive platform for managing all aspects of customer relationships.

Successful Implementations

- A company in the e-commerce sector successfully implemented HubSpot CRM to track customer interactions across multiple touchpoints, leading to improved customer engagement and sales.

- A software development firm utilized HubSpot CRM to streamline their lead generation process and enhance collaboration between sales and marketing teams, resulting in increased conversion rates.

Integration Capabilities

- HubSpot CRM offers integrations with popular tools like Gmail, Outlook, and Zapier, enabling seamless communication and data synchronization across different platforms.

- Businesses can integrate HubSpot CRM with their website to track customer behavior and personalize interactions based on individual preferences, enhancing the overall customer experience.

- HubSpot CRM also integrates with third-party applications such as Shopify and Slack, allowing businesses to extend the functionality of the CRM and tailor it to their specific needs.

Microsoft Dynamics 365 CRM

Microsoft Dynamics 365 CRM is a powerful cloud-based CRM platform that offers a wide range of modules to help businesses manage their customer relationships effectively.

Various Modules Available

- Sales: Helps in managing leads, opportunities, and sales pipelines efficiently.

- Customer Service: Enables businesses to provide excellent customer support and resolve issues promptly.

- Marketing: Allows for targeted marketing campaigns and automation of marketing processes.

- Field Service: Facilitates the management of field operations and service appointments.

- Project Service Automation: Helps in managing project delivery and resource allocation.

Pricing Structures

Microsoft Dynamics 365 CRM offers flexible pricing options based on the specific needs of businesses. The pricing structures can vary depending on the number of users, required modules, and additional customization or integration requirements. Compared to other cloud-based CRM platforms, Microsoft Dynamics 365 CRM may have a higher initial cost but can provide a more comprehensive solution for larger enterprises.

Customization Options

- Custom Entities: Businesses can create custom entities to store specific information unique to their processes.

- Workflows: Automation of repetitive tasks and processes through customizable workflows.

- Integration: Seamless integration with other Microsoft products like Office 365 for enhanced productivity.

- Extensions: Ability to extend the functionality of the CRM platform through third-party apps and extensions.

Zoho CRM

Zoho CRM is known for its ease of implementation and user-friendliness, making it a popular choice among businesses of all sizes. The intuitive interface and customizable features allow users to quickly adapt to the platform without extensive training, resulting in a smooth transition for teams.

Industries Benefiting from Zoho CRM

- Real Estate: Zoho CRM helps real estate agents manage leads, track properties, and streamline communication with clients.

- Retail: Retail businesses use Zoho CRM to track customer interactions, manage inventory, and create targeted marketing campaigns.

- Consulting Services: Consulting firms benefit from Zoho CRM’s project management tools, client communication tracking, and lead nurturing capabilities.

Automation Features in Zoho CRM

- Zoho CRM offers workflow automation to streamline repetitive tasks, such as lead assignment, email notifications, and follow-up reminders.

- Automation rules in Zoho CRM enable businesses to set triggers and actions based on specific criteria, ensuring timely responses to customer inquiries and efficient lead management.

- Integration with third-party apps allows for further automation, such as syncing calendar events, social media interactions, and customer support tickets.

Oracle CRM

Oracle CRM provides robust scalability options for growing businesses, allowing them to easily expand their CRM capabilities as their operations grow. With flexible deployment options and customizable features, Oracle CRM can adapt to the changing needs and complexities of an evolving business environment.

Scalability Options

- Oracle CRM offers scalable solutions that can accommodate the needs of small businesses as well as large enterprises.

- Businesses can easily add or remove users, customize workflows, and integrate additional modules to meet their evolving CRM requirements.

- Oracle CRM’s cloud-based platform ensures that scalability is seamless and efficient, allowing businesses to scale up or down as needed without disruptions.

Reporting and Analytics Capabilities

- Oracle CRM provides advanced reporting and analytics tools that offer real-time insights into customer data, sales performance, and marketing campaigns.

- Businesses can create custom reports, dashboards, and visualizations to track key metrics, identify trends, and make data-driven decisions.

- Oracle CRM’s analytics capabilities enable businesses to optimize their sales and marketing strategies, improve customer engagement, and drive revenue growth.

Security Measures

- Oracle CRM prioritizes data security and privacy, implementing robust measures to protect customer data from unauthorized access, breaches, and cyber threats.

- Encryption technologies, access controls, and authentication protocols are used to safeguard sensitive information stored in the CRM system.

- Regular security audits, updates, and compliance certifications ensure that Oracle CRM meets industry standards and regulations for data protection.

Customization and Integration Capabilities

Customization and integration capabilities play a crucial role in cloud-based CRM platforms to tailor the system according to specific business needs and seamlessly integrate with other tools and systems.

Importance of Customization

Customization allows businesses to adapt the CRM platform to their unique processes and requirements. It enables the addition of custom fields, workflows, and modules to better capture and manage data specific to the business operations.

- Customizing dashboards to display key metrics and reports relevant to the business.

- Creating custom objects to track unique data points and relationships.

- Configuring automation rules to streamline processes and improve efficiency.

Third-Party Integrations

Cloud-based CRM platforms often offer a wide range of third-party integrations to connect with other tools and systems used within the organization. Common integrations include:

- Integration with email marketing platforms like MailChimp or Constant Contact for seamless campaign management.

- Integration with accounting software such as QuickBooks or Xero for syncing financial data.

- Integration with customer support tools like Zendesk or Freshdesk for a unified customer service experience.

Challenges and Benefits of Integration

Integrating cloud-based CRM platforms with existing systems can present both challenges and benefits. Some of the key points to consider include:

- Challenges:

- Benefits:

Ensuring data consistency and accuracy across integrated systems.

Managing compatibility issues between different platforms.

Training employees on using the integrated systems effectively.

Streamlining processes by eliminating manual data entry between systems.

Improving data visibility and accessibility across departments.

Enhancing customer experience through a unified view of customer interactions.

Mobile Accessibility and User Experience

In today’s fast-paced business environment, mobile accessibility plays a crucial role in ensuring that sales teams can stay connected and productive while on the go. Let’s delve into the mobile responsiveness and user experience of the top cloud-based CRM platforms.

Salesforce CRM

Salesforce CRM offers a highly responsive mobile application that allows users to access key CRM functionalities on their smartphones and tablets. The user interface is intuitive, providing a seamless experience for users to view customer information, update records, and track sales activities while on the move. The mobile app’s design and navigation are optimized for mobile devices, enhancing user experience and productivity.

HubSpot CRM

HubSpot CRM also provides a mobile app that enables users to manage contacts, deals, and tasks from their mobile devices. The app offers a clean and user-friendly interface, making it easy for sales reps to access important information and collaborate with team members on the go. With features like real-time notifications and activity tracking, HubSpot CRM’s mobile app enhances user experience and ensures that sales teams can stay informed and engaged.

Microsoft Dynamics 365 CRM

Microsoft Dynamics 365 CRM offers a mobile app that allows users to access CRM data, manage leads, and track sales activities from anywhere. The app’s interface is well-designed, with a focus on providing a seamless user experience across different devices. Sales reps can easily update records, view customer insights, and communicate with prospects on the go, thanks to the mobile app’s responsiveness and intuitive navigation.

Zoho CRM

Zoho CRM’s mobile app is designed to provide users with easy access to CRM features and tools on their mobile devices. The app’s interface is user-friendly, allowing sales teams to manage contacts, deals, and tasks efficiently while away from their desks. With features like offline access and customizable dashboards, Zoho CRM’s mobile app enhances user experience and empowers sales reps to stay productive even when they are not in the office.

Oracle CRM

Oracle CRM offers a mobile app that enables users to access CRM data and collaborate with team members on the go. The app’s interface is sleek and modern, providing users with a seamless experience when accessing customer information and sales data from their mobile devices. With features like real-time updates and offline access, Oracle CRM’s mobile app enhances user experience and facilitates better communication and productivity for sales teams.

Impact of Mobile Accessibility on Enhancing Customer Interactions and Sales Productivity

Having mobile accessibility to CRM platforms is essential for enhancing customer interactions and sales productivity. Sales reps can quickly respond to customer inquiries, update information in real-time, and access critical data while in the field, leading to improved customer satisfaction and increased sales efficiency. Mobile accessibility ensures that sales teams can stay connected, informed, and productive, ultimately driving better results and stronger relationships with customers.

Customer Support and Training

Customer support and training are crucial components when it comes to maximizing the benefits of cloud-based CRM platforms. Vendors offer various options to assist users in resolving issues and optimizing their CRM usage.

Customer Support Options

- 24/7 Online Support: Most cloud-based CRM platforms provide round-the-clock online support through chat, email, or ticketing systems.

- Phone Support: Some vendors offer phone support for immediate assistance with technical or operational queries.

- Community Forums: Users can engage with a community of fellow users to seek advice, share best practices, and troubleshoot common issues.

Training Resources

- Online Tutorials: Vendors often offer a library of online tutorials and guides to help users navigate the CRM platform effectively.

- Webinars and Workshops: Interactive webinars and workshops are conducted to provide in-depth training on specific features and functionalities.

- Certification Programs: Some vendors offer certification programs to help users become proficient in using the CRM platform.

Best Practices

- Utilize Online Resources: Take advantage of online tutorials, knowledge bases, and forums to troubleshoot issues independently.

- Attend Training Sessions: Participate in webinars, workshops, and certification programs to deepen your understanding of the CRM platform.

- Engage with Support: Don’t hesitate to reach out to customer support for assistance whenever you encounter challenges or have questions.

Last Word

In conclusion, Top Cloud-Based CRM Platforms offer a transformative approach to customer relationship management, empowering businesses to streamline processes, enhance customer interactions, and drive sales productivity. With the diverse range of platforms available, each catering to unique business needs, the future of CRM is undoubtedly in the cloud.